About Us

About Us

DIGITAL EDGE DENTAL LAB

Constant Drive To Innovate

We are a fully digital lab that uses rapidly evolving technology to manufacture the highest quality dental implant restorations. Our lab is consistently striving to utilize the newest technology, superior equipment, and the highest quality materials in the dental industry.

Mark Nelson

Mark’s Bio

Mark Nelson, CDT

Mark Nelson began his dental career over 25 years ago where he quickly advanced in a management capacity. He managed the denture department for a 90+ person commercial lab in Portland, Oregon. While there, Mark was actively involved in product development and participated in leading instructional seminars with Prosthodontists. He assisted a dental professor/DDS from Oregon Health and Science University (OHSU) in his spare time to help offer a different perspective and guide students in the removable department on occasion, in addition to performing chairside evaluations and treatment planning on difficult cases at different Doctor practices. Clear Choice Implant Centers recruited Mark to be their National Implant Bar Manager. While at Clear Choice, he created the department from the ground up while working closely with Nobel Biocare and personally designed over 2000 all-on-4 titanium bars.

He received advanced training on bar designs at the Nobel training facility in Mahwah, NJ. Mark created the protocols and lab procedures for all of the Clear Choice centers to use. However, involvement with a high volume, specific focused lab did not allow Mark the freedom to work with patients from start to finish or be more progressive in all aspects of digital dentistry. From there, Mark relocated to Arizona as the In-House Lab Manager for a large implant center where he established, designed and built the lab from the ground up. He had the opportunity to work closely with a talented & knowledgeable team to treatment plan and work with patients chairside, in addition to creating new processes and workflows. Through his research and development, he created the procedures and workflows to deliver the patient within 24 hours a TRUE next day fixed full arch PMMA hybrid with titanium bar.

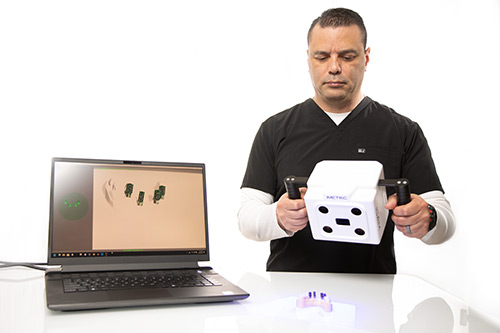

Selected because of his skills and industry insight, Mark was asked to serve as a Beta Tester for some of the leading scanner and design equipment and software in the industry. Mark was the first lab technician in North America to use and create workflows for the iCam4D Beta camera. One of the prerequisites to use the beta camera was being proficient in Exocad and troubleshoot any technical difficulties since there were no manuals or workflows in place.

EQUIPMENT

Imetric ICam4D: The ICam4D revolutionizes the workflow for multi-implant restorations with perfect full arch implant impression in under 10 seconds with photogrammetry allowing accuracy in our fully digital workflow.

3Shape Trios 5: The trios 5 enables us to quickly and accurately build a precise 3D model of your patient’s teeth or edentulous arch. It is critical to the digital workflow.

Imetric Box Scanner: This device transforms physical impressions or models into digital STL files, allowing us to convert conventional analog cases into a digital workflow.

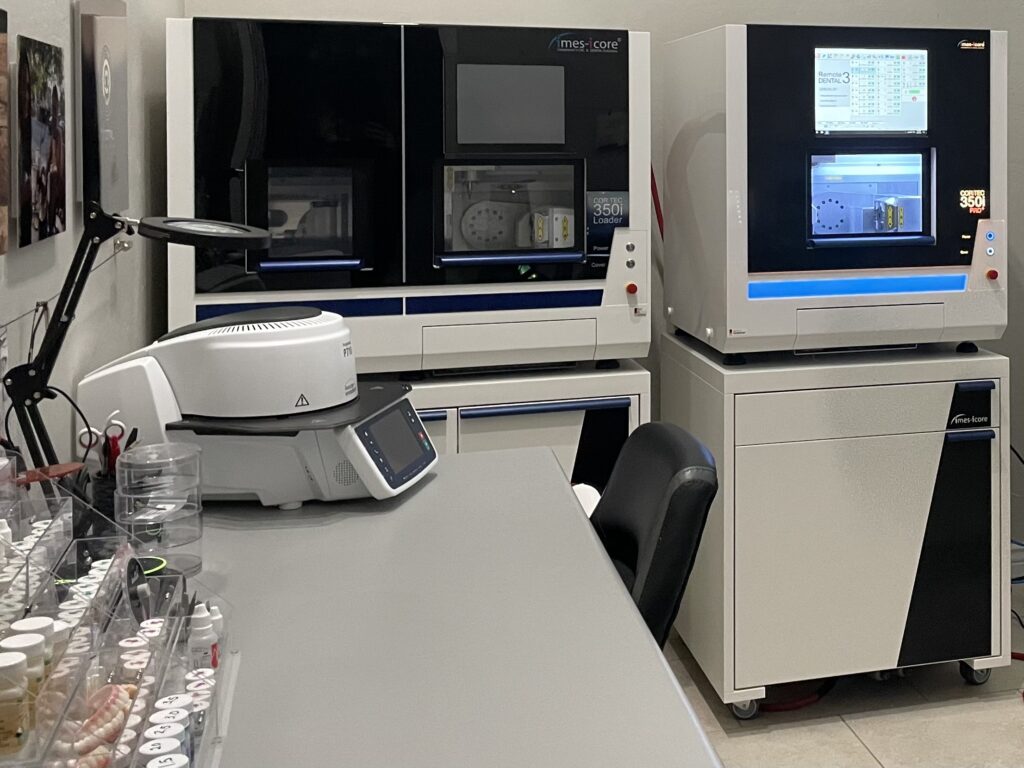

Imes-icore 350i Pro+: Wet or dry milling with a zero-point clamping system that offers maximum flexibility for customization and intricate designs.

Imes-icore 350i Loader: With the fully automatic 6-position blank changer, the system enables versatile machining in 24-hour operation.

Dekema 674i: Versatile furnace that provides quality, precision, and durability. An ideal furnace for manufacturing zirconia full arch bridges and higher volume sintering requirements.

Digital Lab Mobile 3D Printer: High-speed and accuracy. Full arch hybrids printed in under 25 minutes allowing us to deliver “Teeth in an hour.”

Envisiontec: The Envision One features cDLM technology utilizing oxygen to reduce the separation between layers and to printed continuously. This prevents weak points and creates smooth surfaces with incredible strength for long term use in the mouth. All parts printed have Isotropic properties giving accuracy and strength..

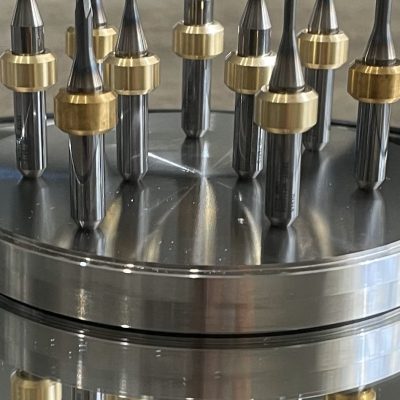

OSG Tools: OSG is a top manufacturer of burs in the aerospace industry. With skills and industry insight, Mark was asked by them to serve as a Beta Tester and assist with research and development to create burs for the dental mills. OSG is bringing in their experience and breaking into the dental industry looking to create innovative burs that will provide better surface quality with extended longevity of life

Testimonials

What Our Customers are saying

“The work that you did on Rask and Swenson is literally the best work that I have ever been a part of! the patients are over the moon how happy they are. You are truly a master!”

– Dr. Lee Smith, HollowBrook Dental